PRODUCTS

Packed Tower Internals

TPT PACIFIC designs and supplies all kind of high performance Packed Tower Internals – various type of Liquid distributor, Packing support,

Bed limiter & Hold down grid, Collector tray & Chimney tray, Feed inlet device and more.

Riser Type Liquid Distributor

A Riser Type Distributor consists of a plate, equipped with circular or rectangular risers for vapor flow and perforations in the floor for liquid flow.

The plate may rest on a support ring or, alternatively, it may be supported on lugs in a manner that provides an annular space for vapor rise

between the distributor and the column wall. A large number of liquid drips provide uniform liquid flow through the orifices with sufficient liquid

head, while the gas risers accommodate expected variations on flow rate, often with a minimum of pressure drop.

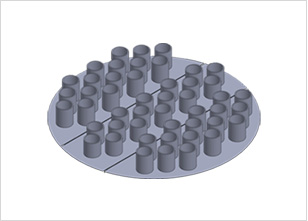

Circular Riser Type

Liquid Distributor (RDC)

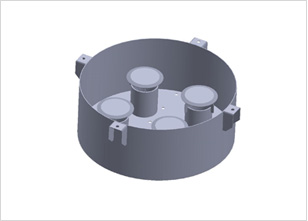

Pan Type Distributor

for Small Column (RPD)

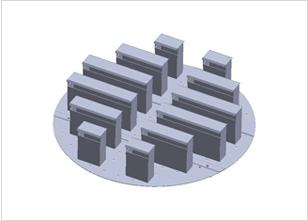

Rectangular Riser Type

Liquid Distributor (RDR)

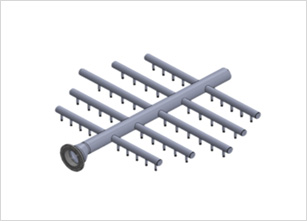

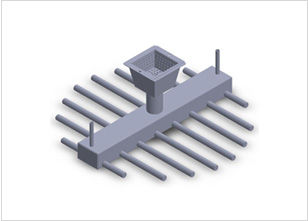

Pipe Orifice Distributor / Spray Header Distributor

Pipe Orifice Distributor has a mainline with lateral pipes branching off to provide a full coverage of the entire tower cross-sectional area.

Orifice holes are usually located at the underside of lateral pipes to direct the flow onto packing. To minimize the possibility of orifice fouling,

it is recommended that feed liquid first passing through a fine strainer to remove any materials that have particle sizes larger than the selected

distribution orifices.

Pressure Type (SND)

(Spray Nozzle)

Pressure Type (PDP)

(Pipe Orifice)

Gravity Type (PDG)

(Receiving Cup)

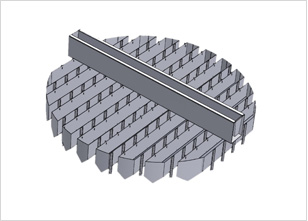

Trough Type Distributor

Most widely used distributors in towers larger than 1 m diameter. The parting boxes distribute the liquid to troughs through

orifices in the bottom floor. The liquid is then fed from the troughs to the packing via orifices that are usually in the bottom

floor or side walls of the troughs. Positioning the feed holes in the trough side walls allows for collection of rust and any

other sediment in the trough bottom floors and avoids plugging of the orifices.

Parting Box with Guide Angle (TDS)

– Orifices are located in the sidewalls of the troughs

– Liquid overflow protection

– Low entrainment

– Fouling resistant

– Multi leveled holes allow for applications requiring high turndown ratio.

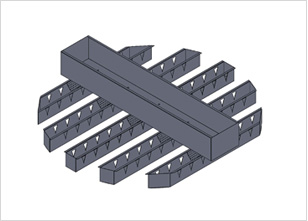

Parting Box with V-notches (TDVN)

– Designed for the highest liquid flow rates apply V-notches

– Specially effective in high liquid flow rates in moderate and severe fouling services

– V-notches are often provided at the top of the trough side walls to provide emergency overflow

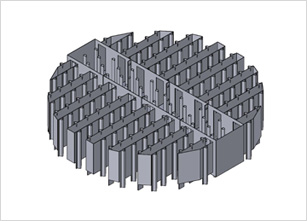

Integrated Parting Box (TDI)

– Feed/parting boxes is integrated into the trough distributor design by positioning at the same level

– Excellent distribution performance

– Fouling resistant

– To conserve space within the tower

- A.

- 1st Floor Hanaro Building, 25, Insadong 5-gil,

Jongno-gu, Seoul, 03162, Korea (Head Office)

- T.

- +82) 2-6356-2550 (Head Office)

- T.

- +82) 52-237-2720 (Shop)

- E.

- tpt@tptpacific.com